Composite Formatting

Composite developers and part fabricators looking to maximize production rates trust us to provide commercial-scale, best-in-class solutions for formatted prepreg composites. From customized slit tape spools to all-in-one ply kits, we supply them with formatted prepregs optimized for their mix of materials, machines, and manufacturing processes. As the only composite formatting company with the proven ability to simultaneously support multiple major aircraft development programs, we’re a qualified slit tape partner on nearly all major automated fiber placement lines, and we know what it take to meet rigorous aerospace quality and fulfillment demands.

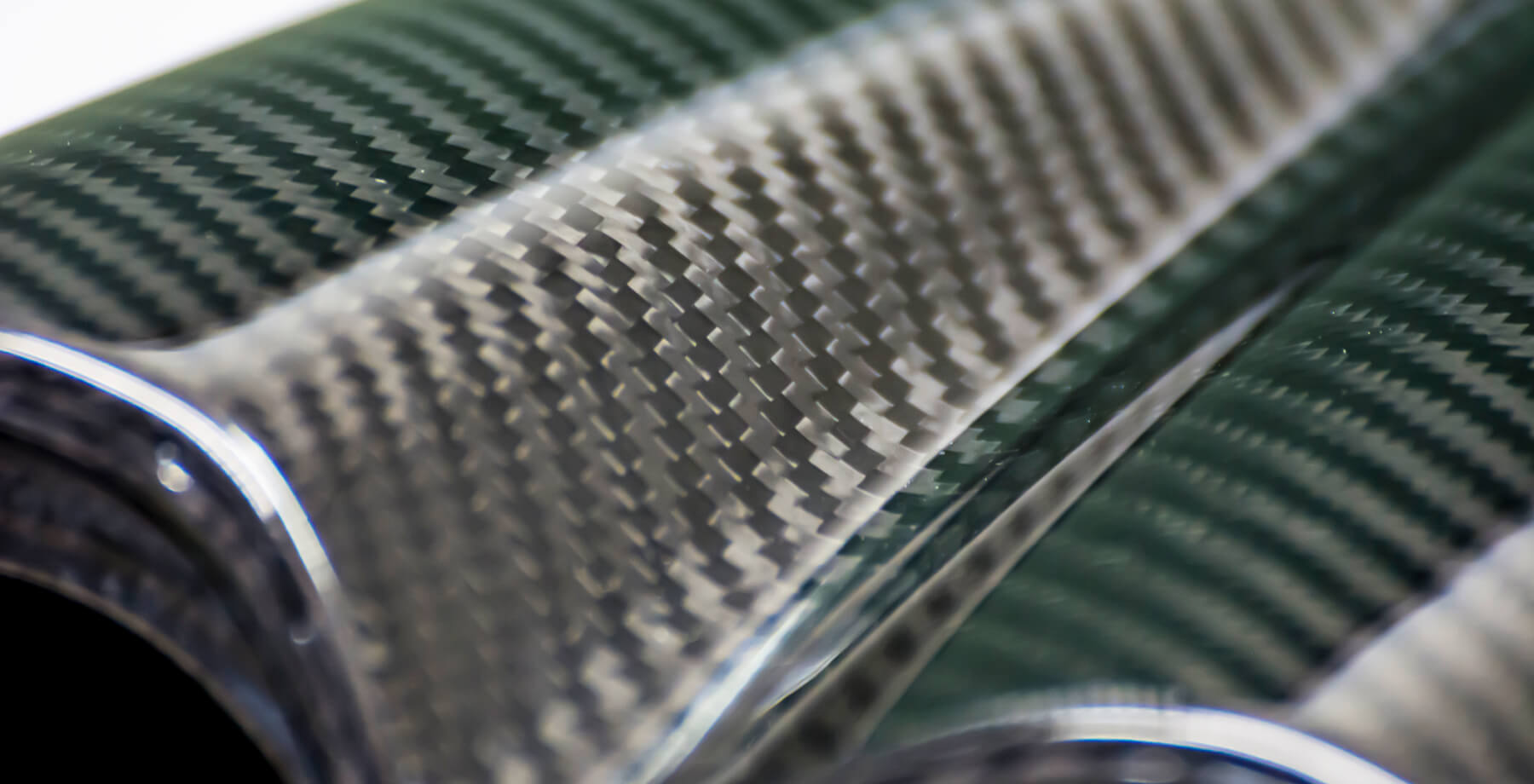

Thermoset Composites

We practically defined the standards for slitting, spooling, and winding thermoset composites for aerospace. We match tape length, winding patterns, liner materials, and spool sizes to meet your specific manufacturing requirements, providing custom-formatted materials that streamlines fabrication workflow, increased production rates, and reduces overall waste.

Thermoplastic Composites

We’re actively developing technologies to slit, spool, chop, or pre-form thermoplastics to aerospace quality levels and commercial-scale volumes for automated fabrication processes.

Composite Preforming

Companies looking to reduce the cost and cycle time of fabricating parts trust us to provide them with preforms ready for downstream manufacturing. Working from customer-supplied files, our automated cutting systems produce precise plies and component structures from composites and other materials, such as adhesive films, aramids, and ceramics. These pieces are then layered, draped, stitched, or autoclaved in-house to produce a preform that is ready for additional machining, such as water jet cutting, or custom-kitted and shipped for final fabrication at the customer’s facility. Combined, these services allow our customers to save time, increase efficiency, and reduce waste.

Ply Cutting & Kitting

Customized, automated table cutting processes produce perfectly cut plies faster and more consistently than traditional hand-cutting methods, while our advanced shape-nesting ensures efficient material usage. Combined with our innovative PlyScan™ technology, the quality of your ply kits is assured and they will arrive per specification for end-product fabrication.

Aerospace-grade Quality & Traceability

Our AS/EN 9100 D and Nadcap certified facilities and exacting quality assurance systems provide controlled receiving, formatting, and shipping environments. And our full lot traceability systems track temperature, out-time, and defect removal from material manufacturer through formatting, allowing for unprecedented historical tracking and yield analysis.

Vendor Managed Inventory Services

Industry leading material management, freezer storage, and inventory control systems eliminate the need for you to invest in non-core production infrastructure and labor.